Chances are, living in Kansas, you have driven by beautiful “amber waves of grain” – also known as wheat fields. Did you know Kansas produces the MOST AMOUNT of wheat in the United States with over 10.8 million tons annually?

I have grown up in Wichita my whole life, and it wasn’t until I had the pleasure of falling for a country boy, that I knew how any of it worked or the amount of WORK that goes into it! To put it into perspective, my husband’s family has 3 big combines, a grain cart, and 4 semi trailers for their operation. It’s a lot of work and a lot of money. Here we are 12 harvests later, and it is one of my favorite times of the year because the process is truly amazing.

And I think it is so important even for those who do not farm to understand how it works. It’s good to know where our food comes from, and that it’s a process and doesn’t just show up at the store.

Wheat harvest typically happens in June when it is hot and dry, ideal weather for cutting wheat. Here are some basics of harvest so the next time you are driving by one of those wheat fields and your tot is yelling “tractor, tractor” and pointing out the window, you can come in like all-knowing super mom and explain about that tractor and what it is doing!

Combines– Combines are the big machines you see with a header on the front of them (circular spikey looking wheel). They are used to cut the wheat. The wheat goes through the header which cuts it, then it goes to the separator which very quickly separates the wheat (the grain) from the chaff (think stem). The grain then shoots into the grain bin, which is housed behind the driver of the combine. It waits here until it is transported to the grain cart.

Grain Cart– The grain cart is the middle man of the cutting/co-op process. The grain cart travels out to the combines (so they can constantly keep cutting) and then the auger (long ole tube like looking piece) spits the wheat from the bin in the combine, into the cart behind a tractor (thus the name for the grain cart). The grain cart then takes the wheat to the semis and uses its auger to put the wheat into the semi trailor. The grain cart typically stays pretty busy as it moves among 3 combines collecting wheat.

Semi– the semi trucks (or smaller trucks depending on the size of the operation) will then take the wheat to the grain elevator at the co-op. When one semi is at the grain elevator, another one is being filled with wheat. It’s a constant state of motion for all the drivers! The co-op will then store the wheat until it is sold. Rides to the co-op are fun because you typically get a popsicle or sucker.

Some wheat will be kept by the farmer and stored so they can have wheat to plant for the next crop. After harvest, the land is disced, then plowed, disced again, fertilized and then field cultivated twice before the wheat is planted in the fall.

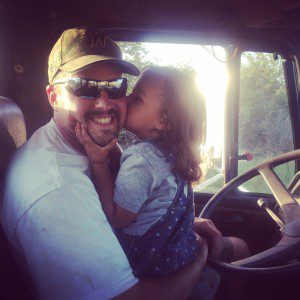

The family aspect is my favorite part of harvest. Meals are taken out to the field and all the guys get off their combines, tractors, and semis to eat on chairs set up in the shade. After the long day, they come in and sit around and talk about the day and figure out how many bushels were cut. My kiddos love riding with their dad or grandpa or uncles and I love that it is a family affair. There is so much that goes into it from meal prep, picking up parts, driving, fixing, servicing. Livelihoods depend on a good harvest, and we as consumers depend on farmers to have a good harvest, whether it be wheat, corn, fruit or vegetables. So next time you are gathered around your table, either buttering your bread, or eating your vegetables, remember that guy in the tractor that you were trying to pass on the road, remember that guy who was out in the field from sun up to sun down, remember that guy that made your babies’ eyes light up when they saw him on that tractor.

And always be sure to thank your local farmer.